OVERVIEW

Setting New Benchmarks in Digital Textile Printing

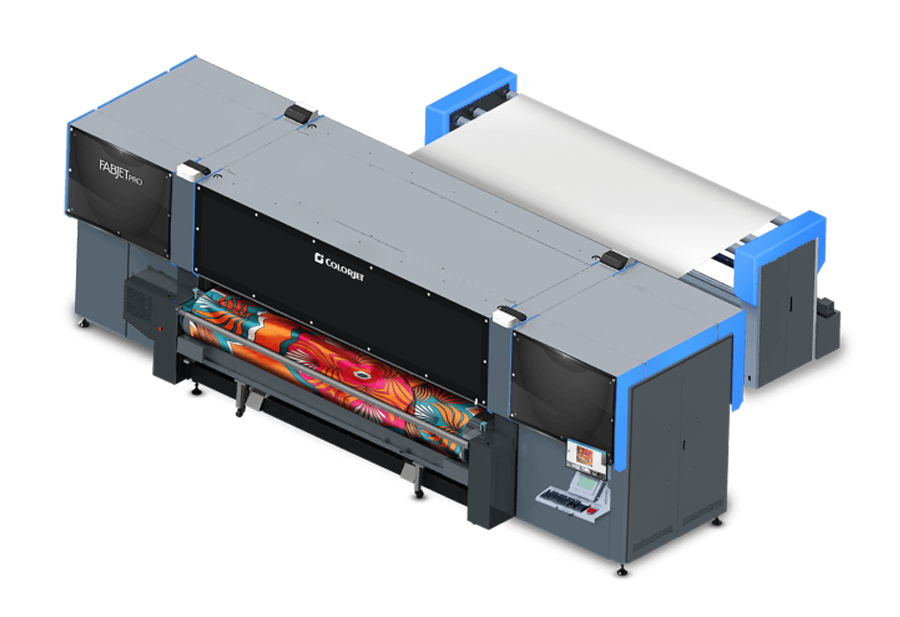

Introducing the FabJet Pro, our latest leap in digital textile printing innovation. With a remarkable production capacity of up to 13,000 square meters per day, the FabJet Pro redefines speed, quality, and efficiency in the industry. Designed for ultra-wide format direct-to-fabric printing up to 3.2 meters.

Equipped with 32 Kyocera and 48 Konica Minolta Print Heads with a sticky belt system, the FabJet Pro ensures unparalleled precision and clarity in every print. This state-of-the-art machine is engineered to meet the highest demands of productivity while maintaining exceptional quality, making it the perfect choice for forward-thinking textile manufacturers seeking to elevate their production capabilities.

FEATURES

Setting New Benchmarks in Digital Textile Printing

Efficient Ink Supply System A complete system enabling the smooth running of the ink and providing high printing stability in high industrial production. Peristaltic pumps help keep the ink supply at a constant level. Negative pressure is detected and adjusted continuously to prevent unwanted ink dropping and spilling of the print head. Efficient Ink degassing system to remove air bubbles in ink tubes to avoid ink starvation assuring the highest print quality.

Controlled Airflow while Printing: Any kind of forced Airflow can result in uneven jetting or cross-firing of water-based inks which can ultimately effect the drop placement.

Capping and Wiping System: Automatic Capping system prevents inks from drying within the print head when the printer is not in use & On-demand wiping system effectively removes ink, dust & debris from the print head.

AIVC® Tech: ColorJet Waveform ensures that the jetting adapts to the viscosity of the inks irrespective of the temperature of the inks.

Micron Precision Encoder: It helps increase accuracy in aligning carriage and belt movement.

Efficient Tension Controller System: The machine features OsciPlusTM precise rollers for optimal tension control and seamless fabric feeding, regardless of GSM, weave, crimp, elasticity, or skewness. The tension roller effectively balances uneven tension, ensuring smooth and consistent media movement.

Modular Feeding System: A modular feeding system to incorporate large-size rolls for continuous printing.

SPECIFICATION

FABJET PRO |

|||||||

CONFIGURATION |

PB8326 |

PB8489 |

PB8329 |

||||

| Printing Technology | Drop-on-demand, Piezo Electric Inkjet |

||||||

| No. of Print Heads | 32 KY

|

48 KM |

32 KM |

||||

| Print Heads | Type | Industrial Grade Jetting Assemblies |

|||||

| Resolution | 600 DPI |

Upto 1400 DPI |

Upto 1400 DPI |

||||

| Height Adjustment | upto 30 mm |

||||||

| Cleaning Method | Pressure Purge and Wiping |

||||||

| Wetting Control | Piezoelectric Actuations |

||||||

| Inks | Types | Reactive |

Pigment/Reactive/Disperse |

Pigment/Reactive/Disperse |

|||

| No of colors | 8 |

8 |

8 |

8 |

|||

| Supply | 2.5 Ltr, Bulk ink Supply System with inline degassing |

||||||

| Fabric | Types | Cotton,Viscose,Polyester,Polyamide,Silk,Wool |

|||||

| Max.Thickness | Upto 5mm |

||||||

| Max.Width | 3200mm |

||||||

| Roll Width | 400mm |

||||||

| Fabric Drying System | Electric Heaters |

||||||

| Operating Interface | Touch screen |

||||||

| Printing Interface | High Speed USB |

||||||

| RIP Software Supported | NeoStampa (Colorjet Editions) |

||||||

| File Format | JPEG, TIFF, BMP/PDF (RGB, CMYK) |

||||||

| Power Supply | 9.5 KW / 3 Φ - 15 A |

||||||

| Operating Conditions | Temperature: 24°C ± 4°C Humidity: 60% ± 10% RH |

||||||

| Printer Dimension / Net Weight | 2835x6572x2041mm (LxWxH) / 6500 Kg approx. |

||||||

| Dryer Dimension / Net Weight | 2550 x 2050 x 1255 mm (LxWxH) / 700 Kg. Approx. /48KW |

||||||

| Feeder Dimension / Net Weight | 1200x3907x1398mm (LxWxH) / 950 Kg approx. |

||||||

| Speed (In Sq. Meter/Hrs) | Print DPI |

Passes |

PB8326 |

PB8489 |

PB8329 |

||

| Mode 1 |

|

2 |

654 |

- |

- |

||

| Mode 2 |

|

3 |

446 |

- |

- |

||

| Mode 3 | 508 x 2400 |

4 |

318 |

- |

- |

||

| Mode 1 | 360 x 720 |

2 |

- |

649 |

434 |

||

| Mode 2 | 360 x 1080 |

3 |

- |

435 |

292 |

||

| Mode 3 | 360 x 1440 |

4 |

- |

312 |

208 |

||

PRODUCT VIDEO

Product video will be uploaded soon...