Colorjet's Complete Solution For Digital Textile Printing

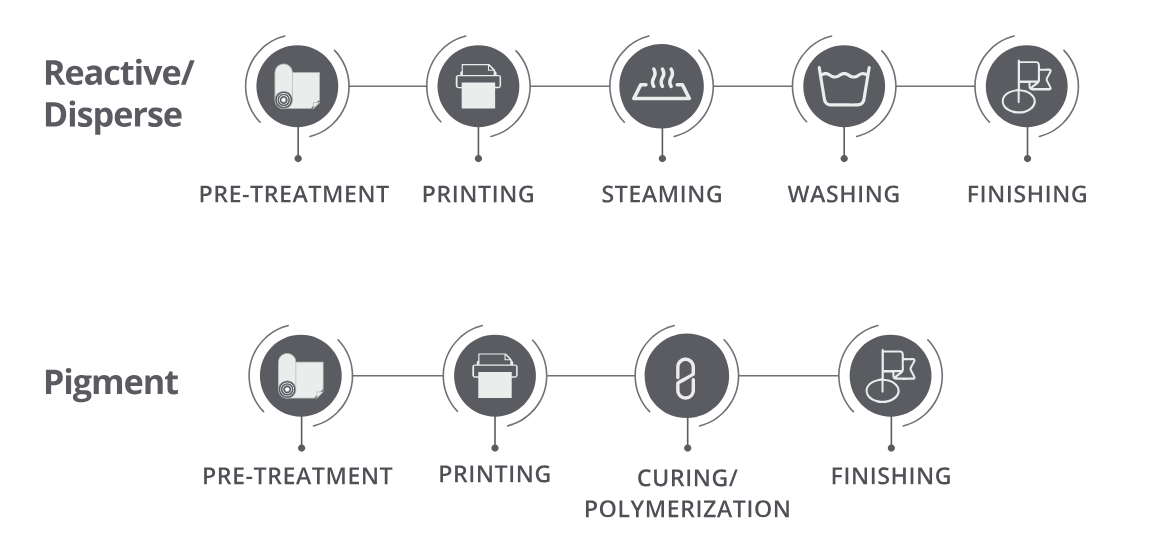

Colorjet's Complete Solution From Pre-To-Post Treatment in Digital Textile Printing Workflow

Colorjet's Complete Solution For Digital Textile Printing stenter to pre-treat RFD fabric for digital printing, loop ager for continuous steaming after printing, continuous polymerizing unit, continuous washing for removing excess dyes and chemicals and vertical drying range to dry the fabric.

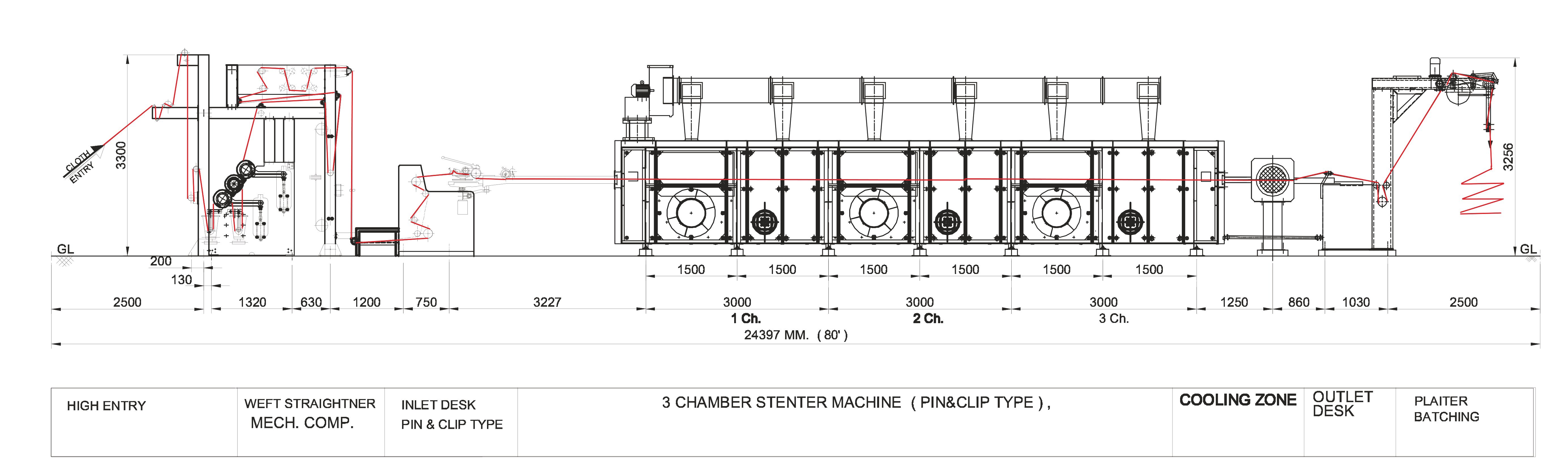

C-Pad

C-PAD is a multipurpose machine. It is used for pre-treating or padding fabric with desired chemical mix for printing, correcting skew and bow in fabric, improving dimensional stability through heat setting, drying and to apply various finishing chemicals to fabric.

Features

- High entry system provides crease free feeding into the machine smoothly and evenly.

- Pressure settings to control the amount of pressure exerted by the rollers on the fabric in the padding mangle.

- Tension regulation system to maintain fabric tension

- Weft straightening mechanism to rectify skew and bow issues present in the fabric.

- Allows operators to set and monitor various parameters, such as speed, temperature, and pressure.

- Robust structure and design for long-term durability.

- Easy access for maintenance and cleaning.

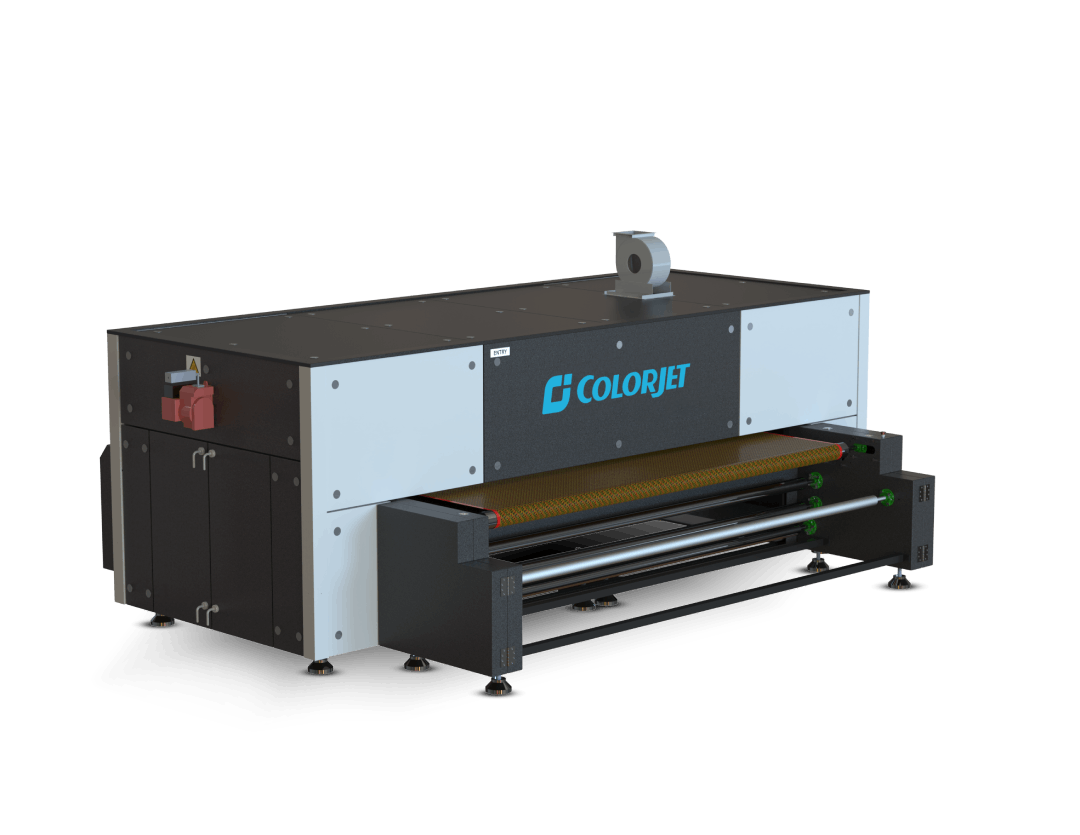

C-Cure

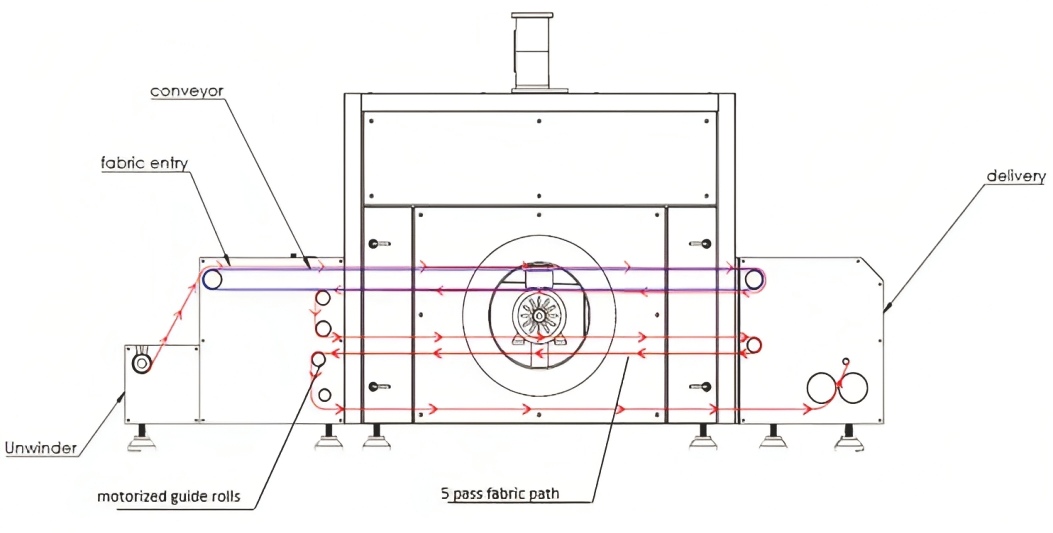

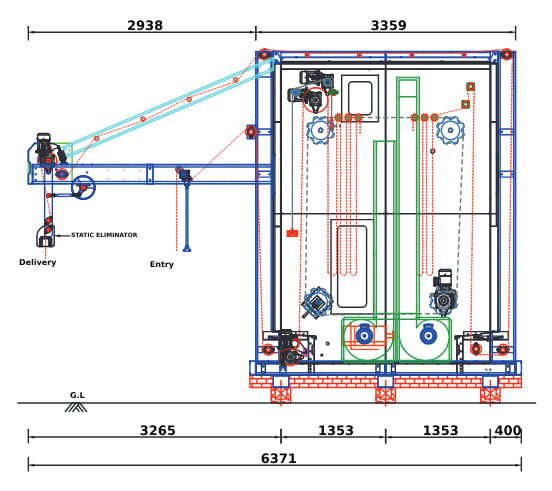

C-Cure machine for curing digital pigment ink prints

C-Cure is designed for curing and polymerizing pigment ink prints, after the printing process, pigment inks require cross-linking polymerization to achieve better fastness.

Features

- A conveyor belt or system for transporting printed substrates to the curing chamber.

- Efficient heating elements for uniform heat distribution.

- Digital control panels or touchscreens for user adjustable setting and monitoring curing parameters.

C-Fix

Loop Steamer for fixing the colour on fabric

C-Fix is a loop steamer designed specifically for the purpose of steaming fabrics to fix the colours after printing . This machine comprises an enclosed chamber in which controlled humidity and temperature are maintained, even as printed fabric is continuously passing through it. Users may manage and customize both humidity and temperature settings for various processing needs.

Features

- Fabric Entry and Exit provided on the similar side for easy operation.

- Suitable for different applications with saturated steam, super-heated steam or just hot air.

- A closed loop ager chamber where the fabric is processed in relaxed form.

- Suitable for steam application on all types of fabrics including knits & made with elastomeric yarns.

- Roof heating adjustment helps to prevent condensation from falling on fabric.

- All rollers are motor driven and are Teflon coated.

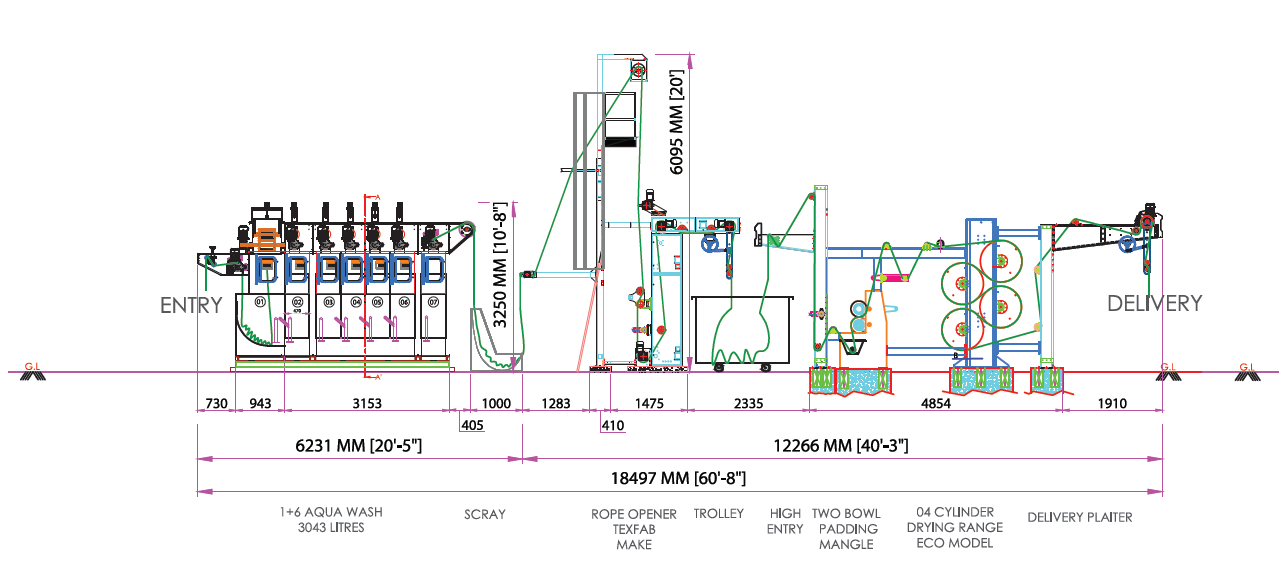

C-Wash

For Washing-Off Unfixed Dyes And Chemicals

The process of Reactive, Acid or Disperse dyeprinting is not complete till all unfixed superfluous dyes are removed. C-Wash effectively washes the printed fabric in a continuous process of successive washes with cold, hot and with detergent water. The multichamber washing line is followed by a rope opener and vertical drying range of hot cylinders.

Features

- Seven washing chambers equipped with squeeze rollers for a thorough multi-stage fabric washing process.

- 2-bowl padding mangle to squeeze out water before multi-cylinder drying range.

- Automatic Rope Opening System to ensure opening of fabric uniformly without any hindrance.

- Fabricated from high quality stainless steel.